Nippon Golf is one of the biggest companies in the business and the maker of arguably the most popular steel shafts available on the US market, especially when we're talking about the N.S. Pro Modus series. The good news for today is that Nippon Golf went a little bit further with innovation and released its latest N.S.Pro Modus³ hybrid shaft made with Graphite On Steel Technology, also known as G.O.S.T., thus bringing their hugely popular bend profile to hybrids.

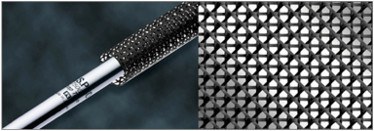

Truth be told, the concept of mixing together graphite and steel to make high-end shafts is not as revolutionary as it may sound for our readers, as the technology has been around for over twenty years, and other companies implemented it in various designs. However, what makes Nippon Golf's approach different from other companies is the process used to combine graphite and steel together to create 1 shaft. To give you a little bit of context, graphite made shafts are crafted by using flags (graphite sheets) which are wrapped around a mandrel and rolled, then compressed with a film; in the next step, they're baked to cure, sanded, and in the final step, a layer of paint is added for better optics. The new N.S.Pro Modus³ hybrid shaft made with Graphite On Steel Technology from Nippon Golf is built without a mandrel, with the interior steel portion running the entire length thus making that piece double; and yes, Nippon Golf employed the same technological innovation with their excellent and ultra-light 750GH WrapTECH.

The new N.S.Pro Modus³ hybrid shaft made with Graphite On Steel Technology from Nippon Golf is built without a mandrel, with the interior steel portion running the entire length thus making that piece double; and yes, Nippon Golf employed the same technological innovation with their excellent and ultra-light 750GH WrapTECH.

The method of combining steel and graphite in the new Modus³ Hybrid delivers a solid feel, as well as tighter dispersion, which is commonly associated with steel shafts, yet you'll benefit from the easy launch/trajectory that's specific to carbon fiber. Basically, the steel/graphite combo is the best of both worlds, giving you all the benefits of both materials, plus a shaft bend profile, that's specially engineered to maximize hybrid performance. The respective bend profile was based on the Tour-proven N.S.Pro Modus³ Tour 105, i.e. the Modus³ Hybrid is designed to deliver an easy launch, enough spin to help you stop longer approaches on greens, and mid trajectory. One of the most important processes in the development of the Modus³ Hybrid is the company's patented adhesive technology. Those ultra-strong adhesives used in the G.O.S.T. tech allows the graphite layers to adhere perfectly to the steel shaft interior, and this wrapping/manufacturing technology makes Nippon Golf different from other companies and separates the Modus 3 Hybrid shaft from the “crowd” so to speak. Also, using steel and graphite makes perfect sense in a hybrid, as graphite is used by all manufacturers in their woods, and steel is the go-to choice in most irons.

And yes, hybrids fit right between woods and irons, thus blending steel and graphite for hybrids shafts is the best invention since sliced bread or something along these lines. In terms of pricing and availability, you can order the Modus 3 Hybrid shafts with constants 41? raw length, .370? tip diameter, and .600? butt diameter for $249.99 MSRP.